Protecting the environment & managing resources

We continuously scrutinise boundary conditions and influencing factors and adjust our targets accordingly. A key cornerstone is the reference to scientifically sound and comprehensible parameters and processes. The collection of our data according to ESG criteria (environmental, social and governance) is in line with the classifications of the Greenhouse Gas Protocol (GHGP). We systematically identify potential for CO2e reduction and derive specific measures that we integrate into our continuous improvement process (PDCA cycle).

We record our greenhouse gas emissions separately in the areas of Scope 1 (direct emissions) and Scope 2 (indirect emissions). By 2026, we will also have further developed the recording of Scope 3 emissions. This will give us a comprehensive overview of our climate impact and enable us to take targeted reduction measures.

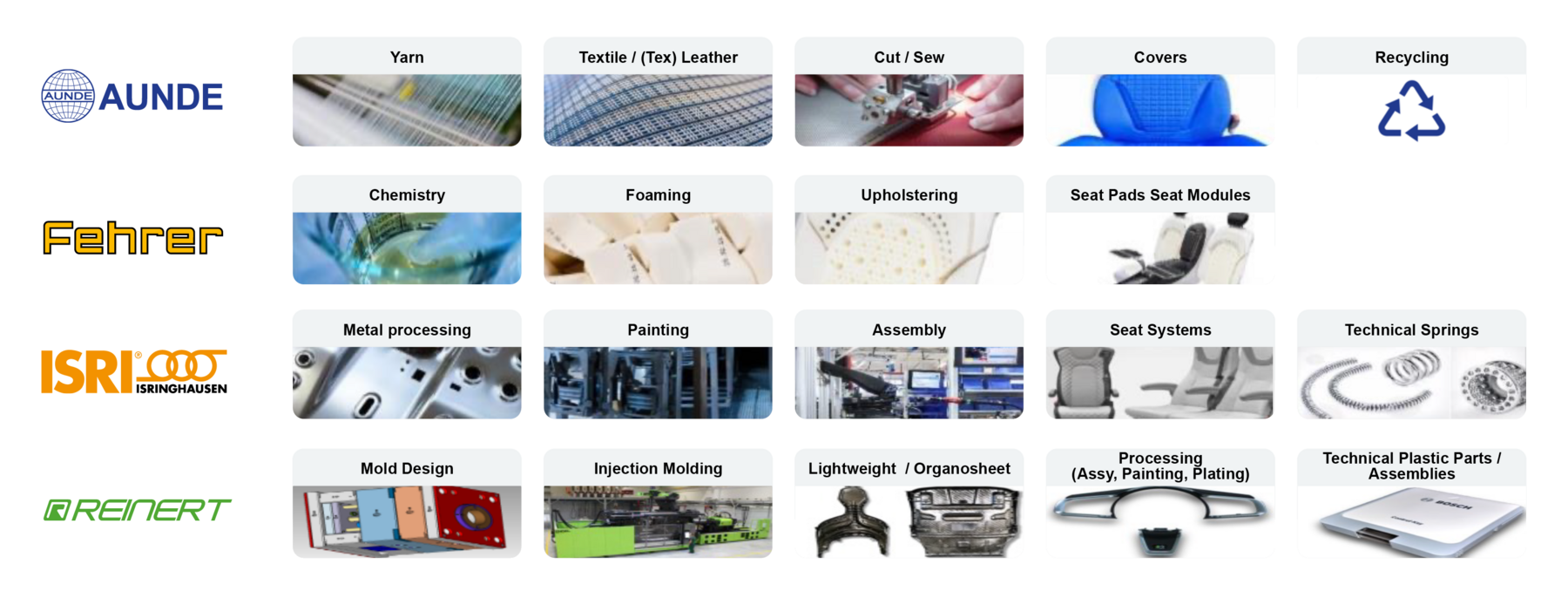

Vertical integration & added value

The AUNDE Group is characterised by remarkable vertical integration and high added value across all business units. An exemplary production chain for the manufacture of a lorry driver's seat begins in the AUNDE business unit with the production of the yarn from which the upholstery fabrics are woven, cut and sewn. The final assembly of the seat system also includes metal frames, springs and pneumatic components from ISRINGHAUSEN production, upholstery and foam components from FEHRER and plastic parts manufactured by REINERT. This vertical integration allows us to comprehensively control and manage the quality and efficiency of our products. Although the business units operate largely autonomously, synergy effects from material procurement and production to final assembly and delivery can be utilised by all AUNDE Group units.